Written by Kevin - Published on May 30, 2024

How to apply the Corexy structure to the laser engraver?

In the world of laser engraving, precision is paramount. Whether you're creating intricate designs or cutting materials with exacting detail, the accuracy of your machine can make or break your project. CoreXY structure—a changer in the realm of motion control systems. This article will walk you through how to apply the CoreXY structure to a laser engraver, boosting its performance and reliability.

What is CoreXY Structure?

Definition and Key Features

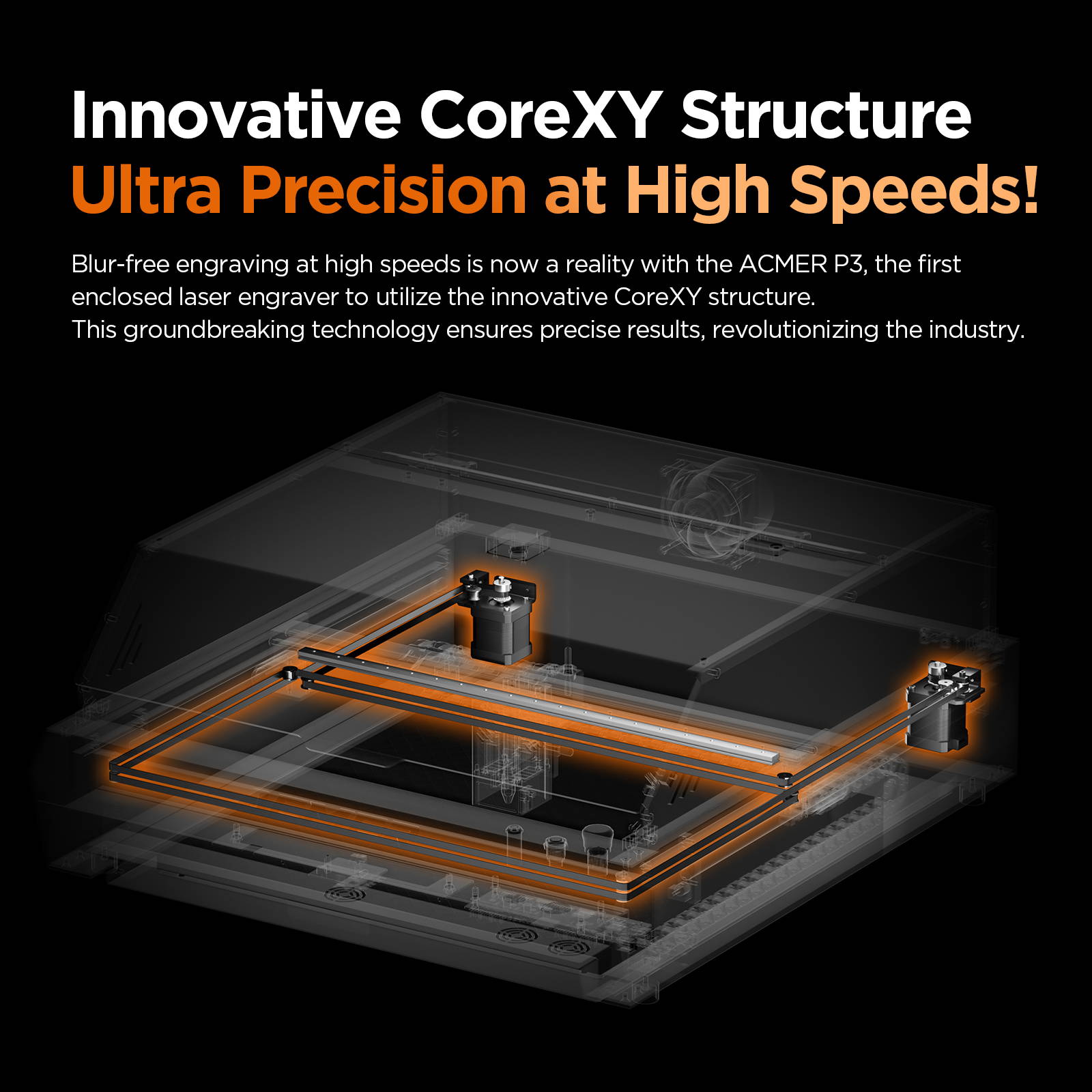

The CoreXY structure is a motion control system that uses a unique belt arrangement to move the laser head. Unlike traditional Cartesian systems where each axis is driven independently, the CoreXY design employs two motors to control both the X and Y movements simultaneously. This results in a more stable and accurate motion system.

Comparison with Other Motion Systems

Compared to H-bot and Cartesian systems, CoreXY offers superior precision and reduced mechanical stress. H-bot systems, while similar, tend to suffer from racking issues due to uneven forces on the frame. Cartesian systems, on the other hand, can be bulkier and less efficient. CoreXY's balanced belt system eliminates these problems, providing a more reliable and high-performing solution.

Benefits of CoreXY in Laser Engraving

Enhanced Precision and Accuracy

The CoreXY design minimizes the inertia of moving parts, leading to more precise control of the laser head. This translates to finer details and cleaner cuts in your engravings.

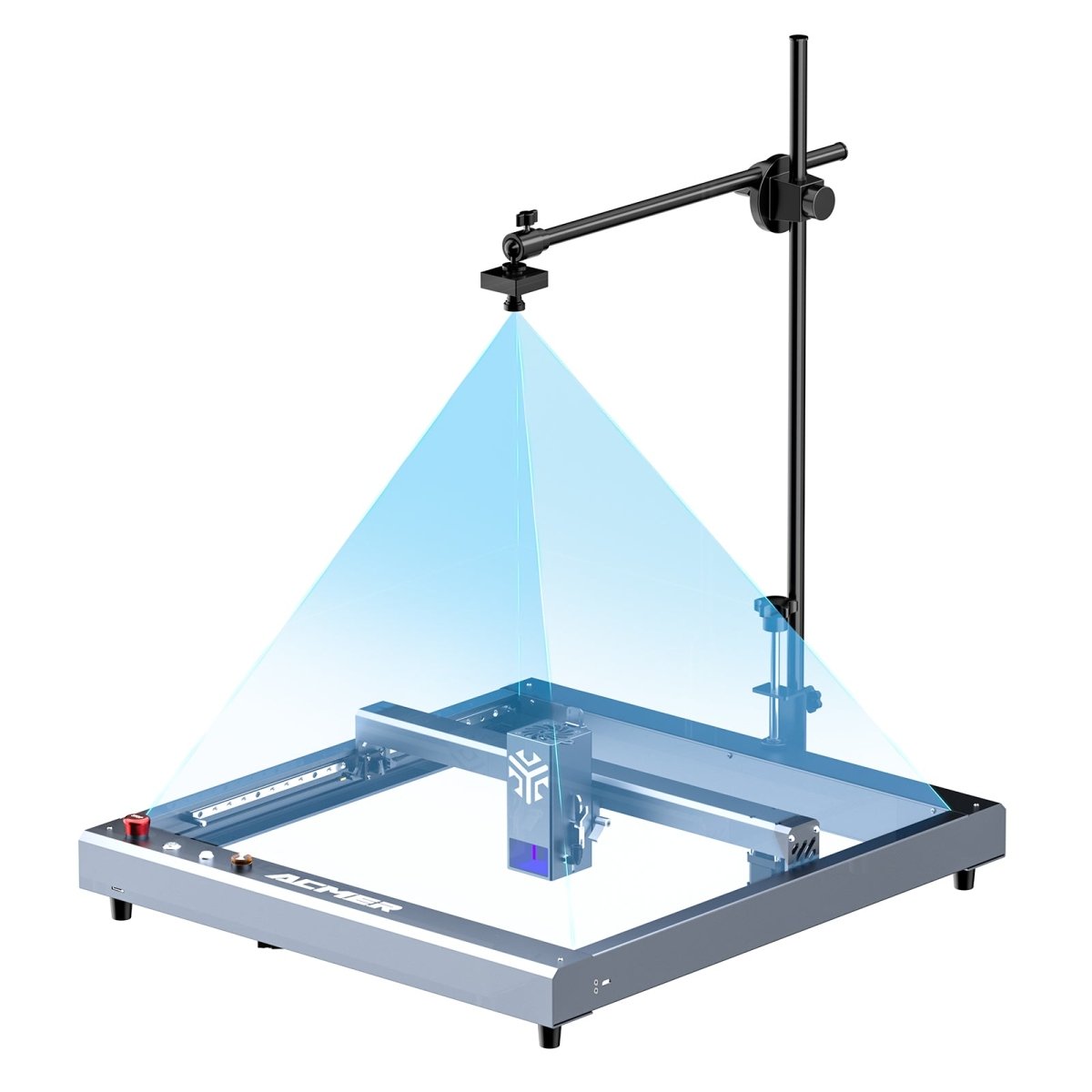

corexy engraving accuracy

Speed and Efficiency

corexy engraving speed

Compact Design

CoreXY setups are typically more compact than their Cartesian counterparts. This allows for a more streamlined machine that can fit into tighter spaces, making it a versatile choice for various workshop setups.

Components Needed for CoreXY Laser Engraver

Frame

As the foundation of the laser engraver, the frame must be strong and precise. Commonly used materials include aluminum extrusions, which are popular for their durability and ease of assembly, and their strength and lightweight properties are well balanced. Steel frames can also be used to increase rigidity, but are heavier and more difficult to operate.

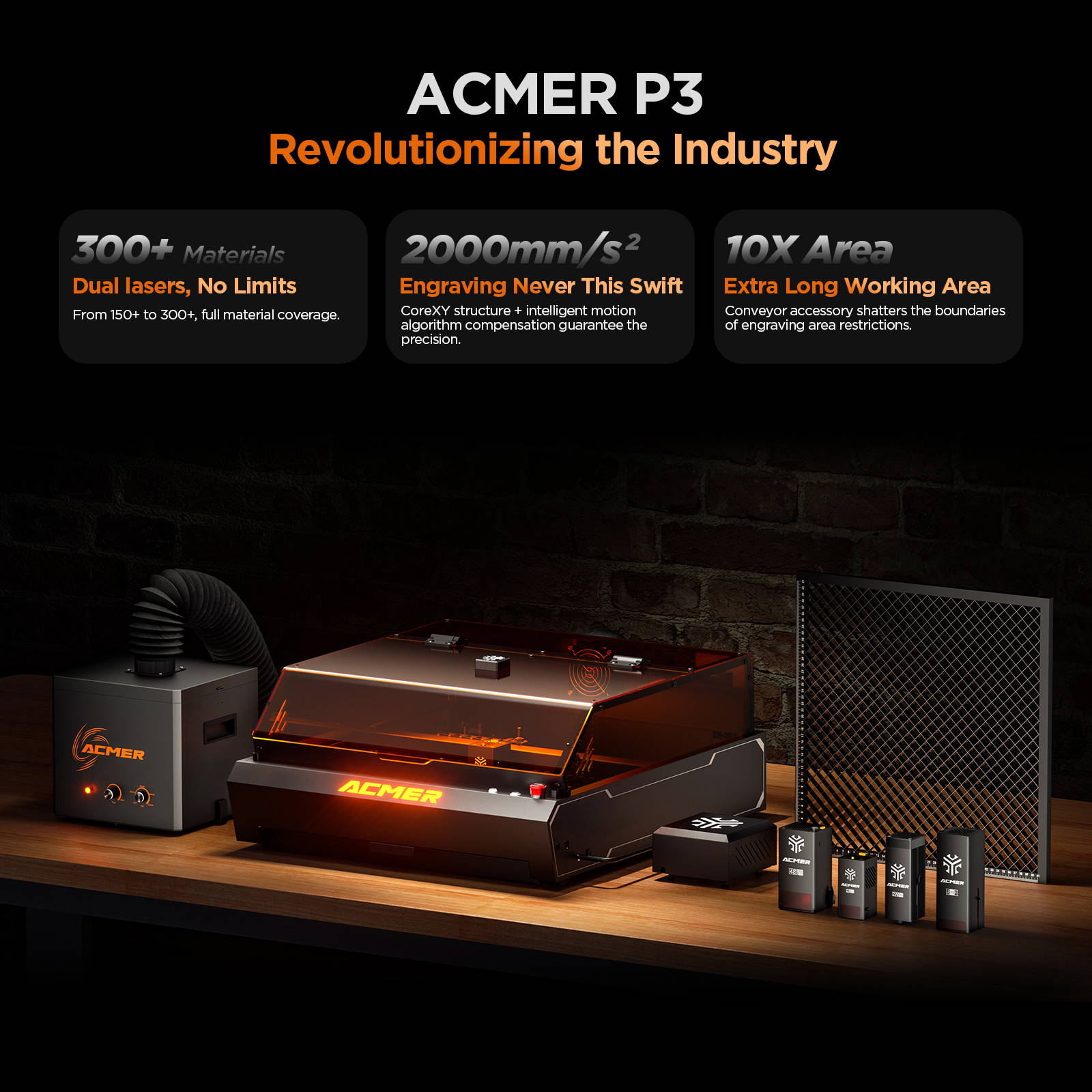

The frame size depends on the maximum engraving area you need. Larger frames offer more versatility, but require more space and materials. The frame body constructed of aluminum profiles used by ACMER P3, with an engraving range of 400*400 and expandable to 4000mm, is the largest in the world. It will be your best choice.

Motors

Need two stepper motors to drive the CoreXY system. NEMA 17 or NEMA 23 stepper motors are commonly used in CoreXY systems. They should provide sufficient torque and have a high step resolution for precise control.

Belts and Pulleys

Belts and pulleys are critical components in the CoreXY system. They need to be high quality to maintain tension and reduce slack, ensuring precise movement. GT2 belts are a popular choice due to their precision and reduced backlash. Ensure they are of high quality to maintain performance. CoreXY structures like the ACMER P3 use a double layer of GT2 belts, ensuring stability and precision at high speeds.

Controller Board

The brain of your laser engraver, the controller board, manages the motors and other components. It's important to choose one that is compatible with CoreXY systems and your chosen firmware.

Laser Module Selection

Engraving and Cutting Requirements

Laser modules range from low power IR laser for engraving to high power diode laser for cutting. Choose according to your material and depth requirements. ACMER P3 is available in diode, IR laser and 2-in-1 diode-IR laser. With a maximum power of up to 48w, it can easily engrave and cut most materials.

Beam Quality and Focus

Good beam quality ensures clean cutting and fine engraving. Adjustable focus gives you more flexibility when working with different materials. ACMER P3 has an engraving accuracy of up to 0.01mm, helping you engrave the finest and cleanest works.

Safety Considerations

Always put safety first, laser housing, protective glasses and interlock devices to prevent accidental exposure to the laser beam. ACMER P3 has Class 1 laser protection certification, in addition to 8 safety protection functions, and has functions such as opening the cover to pause and closing the cover to continue engraving, which is not only safe and worry-free, but also makes the engraving work more satisfying.

Software for CoreXY Laser Engraver

Recommended Software Options

LaserGRBL, LightBurn, and Inkscape are popular choices for controlling laser engravers. They offer various features to suit different needs.

Setting Up Software for First Use

Install the software and configure it to recognize your CoreXY machine. This involves setting the workspace size, homing parameters, and laser power settings.

Integrating with CAD/CAM Programs

For more complex designs, integrate your laser software with CAD/CAM programs like AutoCAD or Fusion 360 for advanced design and toolpath generation.

Maintenance and Troubleshooting

Regular Maintenance Tips

Keep the belts clean and check tension regularly. Inspect the frame and moving parts for wear and tear, lubricating as necessary.

Common Issues and Solutions

Address common issues like misalignment, skipping steps, and inconsistent laser output by referring to troubleshooting guides and community forums.

Upgrading Components

As your skills and needs grow, consider upgrading components like the laser module, controller board, or frame for improved performance.

Which laser engraving machines currently use the corexy structure?

As of 2024, ACMER P3 is the world's first laser engraver using a corexy structure, and it is also the world's first closed dual laser engraving machine.

Conclusion

Incorporating CoreXY architecture into your laser engraver can significantly improve its performance and accuracy. By carefully selecting and assembling the right components, and diligently maintaining your machine, you can achieve outstanding results in your engraving projects. Ready to get started? Read all of the above to get you started with the best-in-class CoreXY laser engraver.

FAQ

What are the advantages of a CoreXY structure over a Cartesian system?

CoreXY systems offer better precision, higher speed, and a more compact design compared to traditional Cartesian systems.

Can I convert my existing laser engraver to a CoreXY system?

Yes, with the right components and some modifications, you can convert a Cartesian laser engraver to a CoreXY system.

What type of laser module should I use for a CoreXY engraver?

The choice of laser module depends on your specific needs, such as the material you plan to engrave and the desired depth of engraving.

How do I ensure my belts are properly tensioned?

Use belt tensioners or adjustable mounts to maintain the correct tension. Regularly check and adjust as necessary.

What software is best for controlling a CoreXY laser engraver?

LaserGRBL and LightBurn are highly recommended for their ease of use and robust features. They also integrate well with CAD/CAM programs.

Related blogs