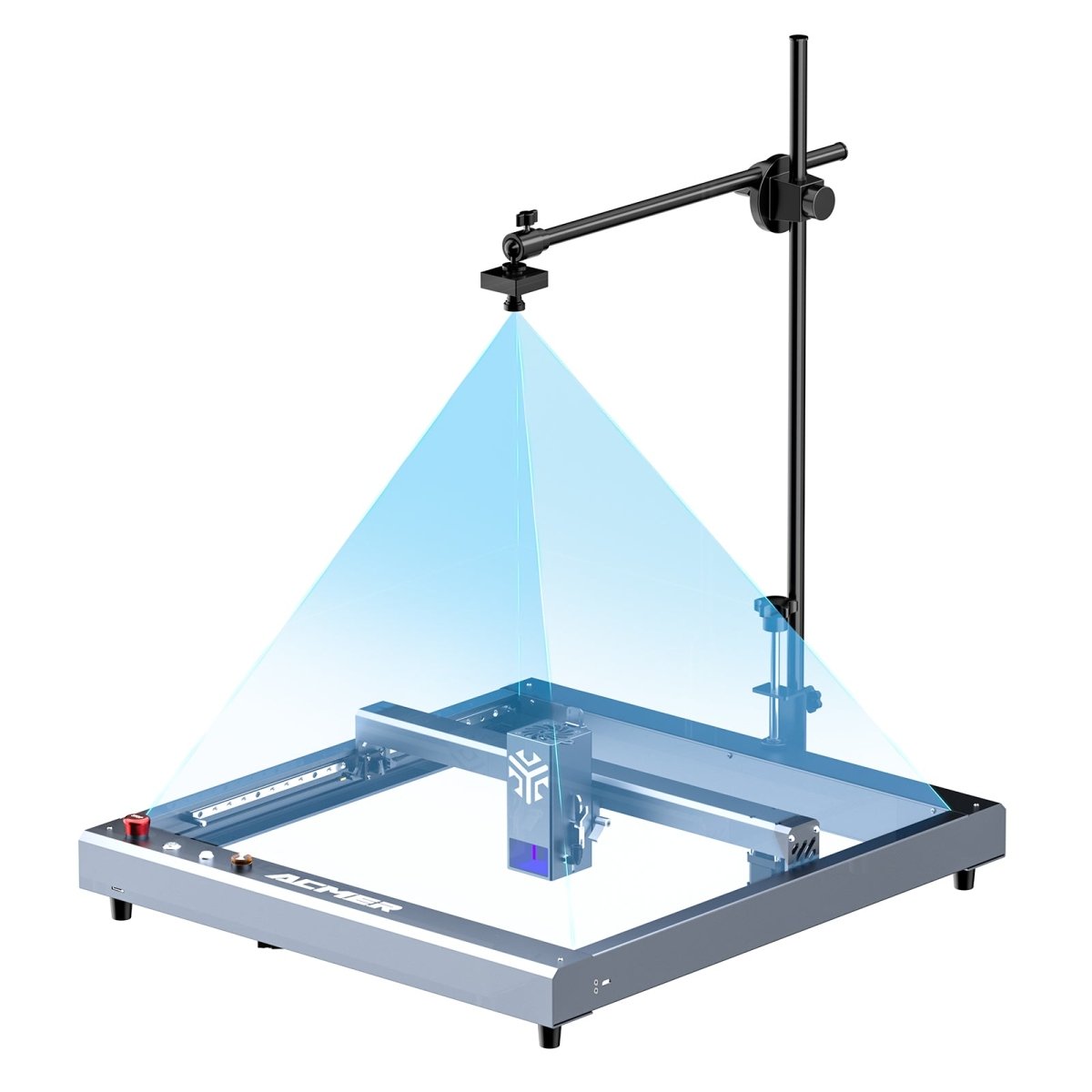

ACMER P2 IR 2w Infrared(IR) Laser Engraver

Guarantee Safe Checkout

Description

- Best budget IR laser engraver in 2024

- Perfect for engraving metal, plastic, rock, acrylic

- With metal rust removal function

- Maximum engraving speed of 30000mm/min

- Pre-assembled laser model

- Ultra-fine laser spot size of 0.03mm

Return Policy

Learn more:https://acmerlaser.com/pages/refund-policy

Reviews