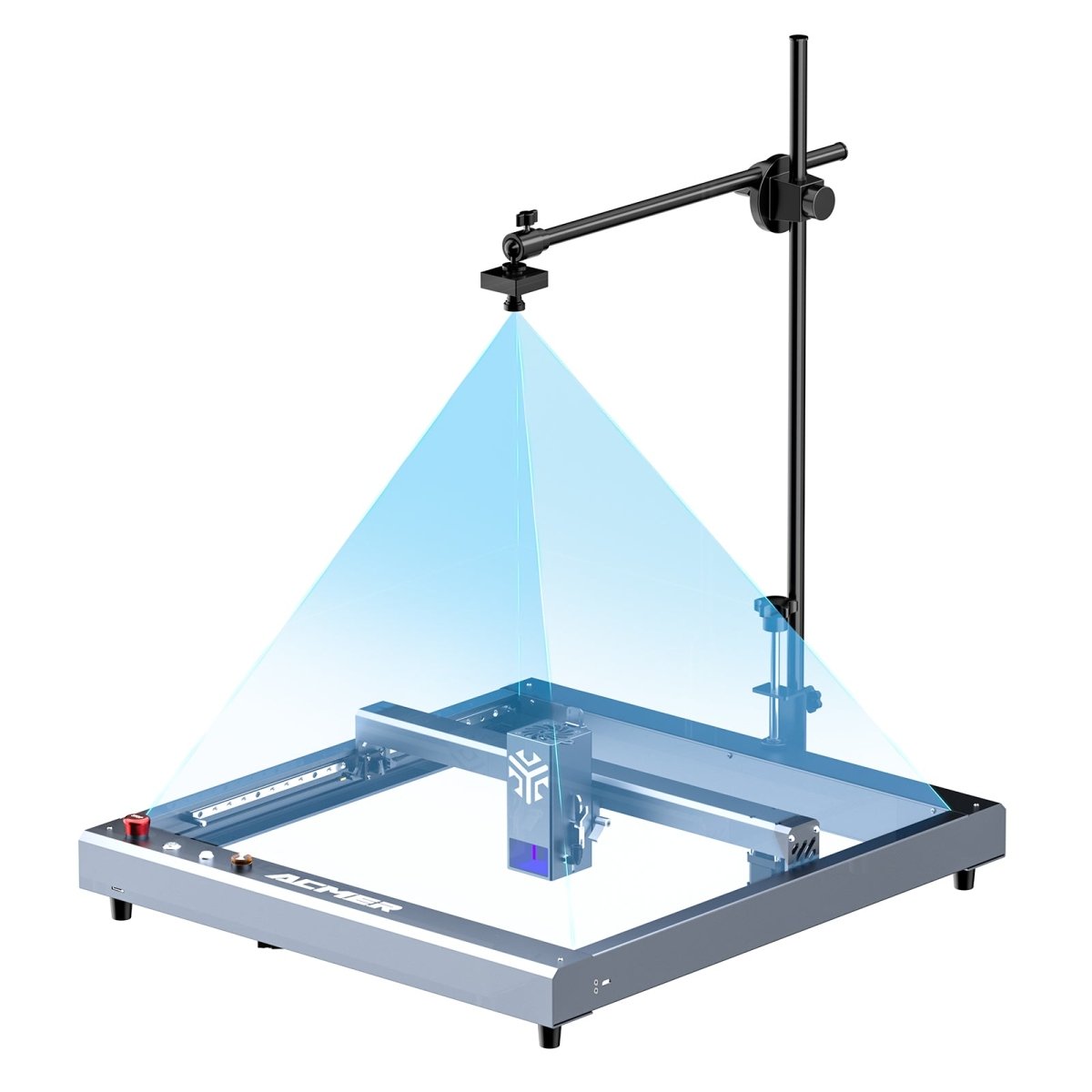

Laser Engraver Materials and Supplies

Laser Engraver Material |The consumables that are suitable for laser engraving machines include acrylic, wood, plywood, glass, aluminum oxide, stainless steel, bamboo, colored paper, kraft paper, ceramic tiles, engraved craft stone slabs, and engraved leather, among others.