Rubber Sheets - DIY

Guarantee Safe Checkout

Rubber Sheets - DIY

Description

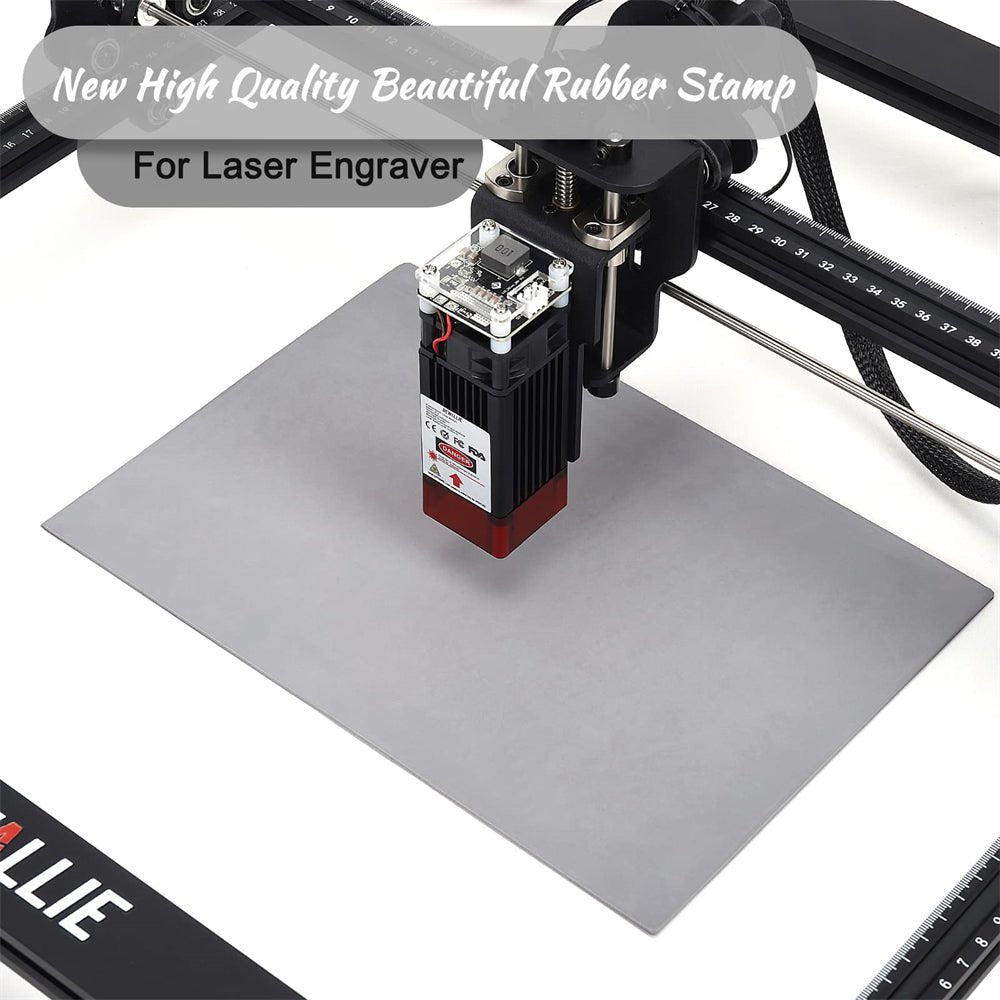

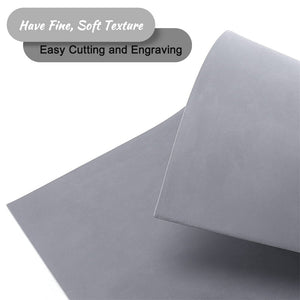

Rubber sheets can indeed be used for laser engraving purposes. Laser engraving on rubber sheets offers several advantages, such as precise and detailed engraving, ease of customization, and the ability to create intricate designs. Here are some key points to consider when using rubber sheets for laser engraving:

Material selection: Choose rubber sheets specifically designed for laser engraving. These sheets are typically made from laser-engravable rubber compounds that produce clean and precise engravings when exposed to a laser beam. Ensure that the rubber sheet is compatible with the type of laser engraving machine you are using.

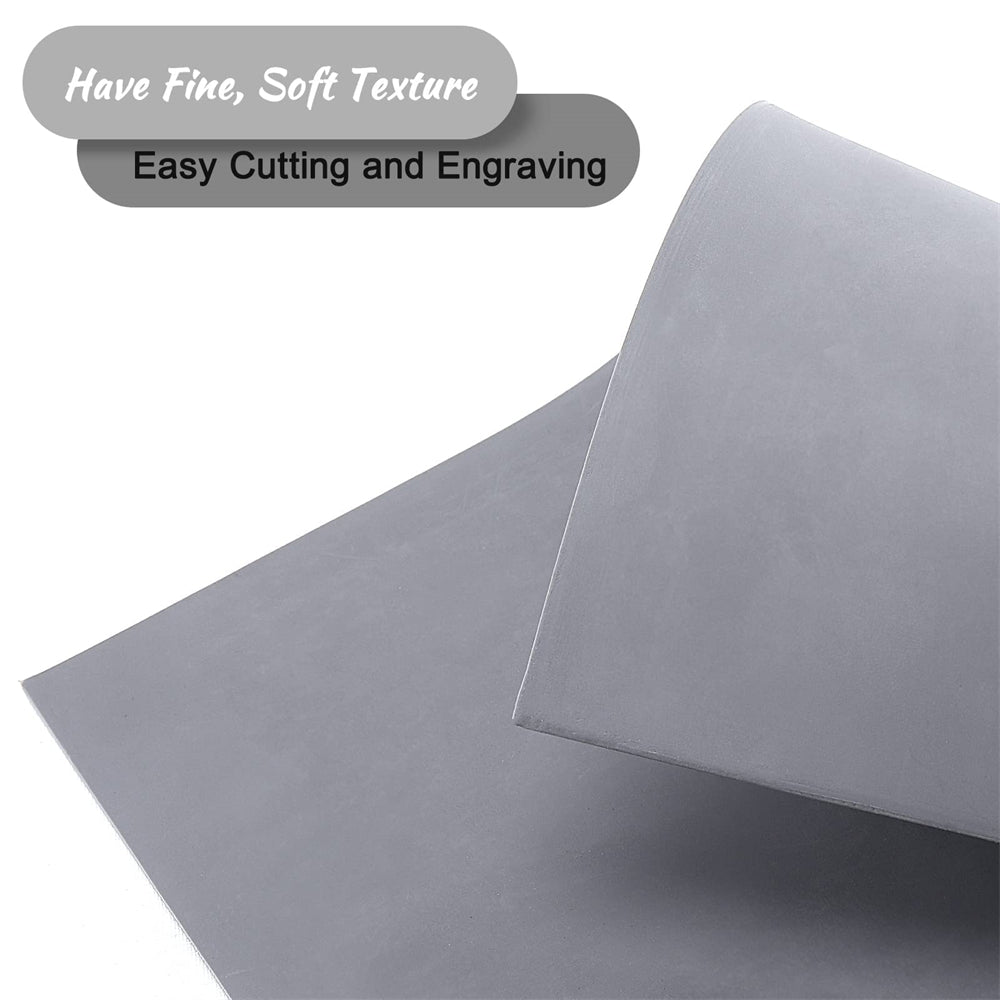

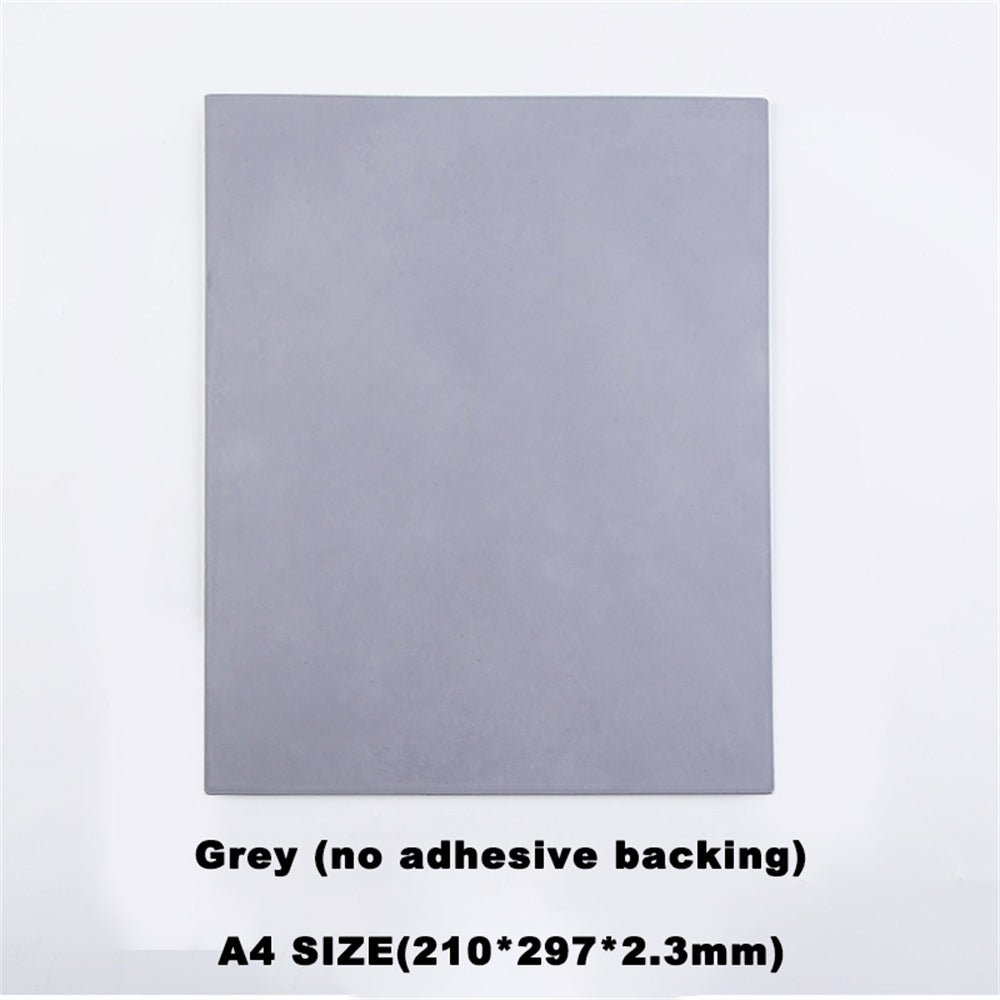

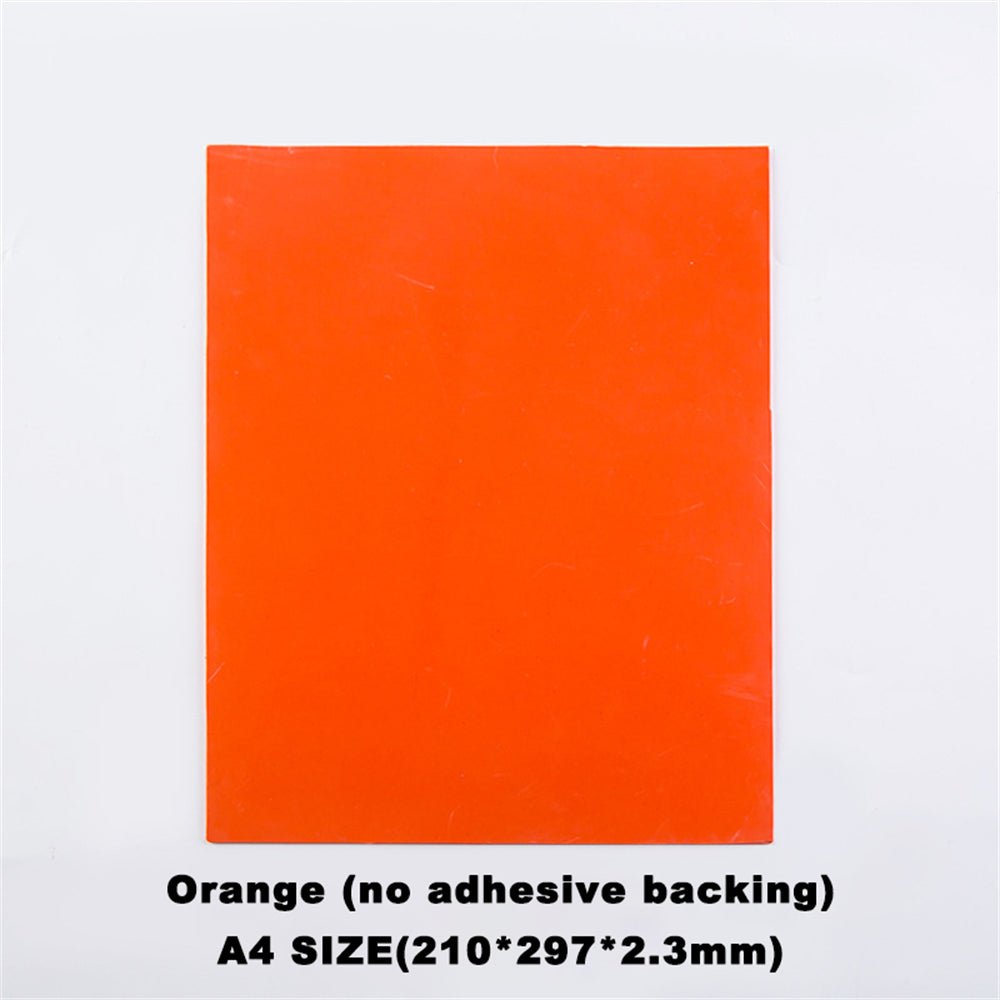

Thickness: Rubber sheets for laser engraving come in various thicknesses. Thicker sheets are more durable and can withstand multiple engraving passes, while thinner sheets allow for finer details. Consider the depth and level of detail required for your engraving project when selecting the appropriate thickness.

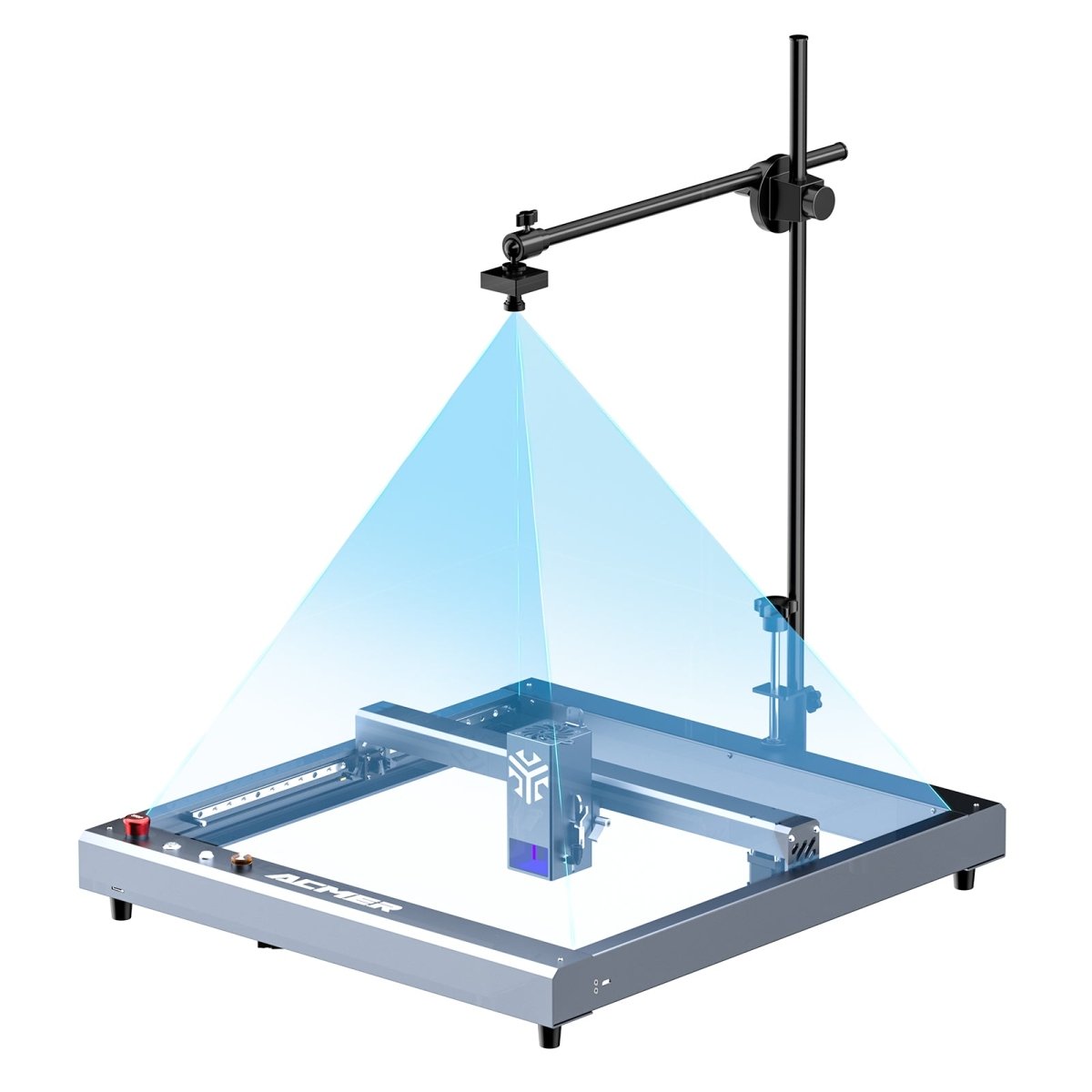

Engraving settings: Adjust the laser engraving machine settings according to the specific rubber sheet being used. Parameters such as laser power, speed, and frequency may vary depending on the rubber sheet's composition and thickness. It's important to conduct some test engravings on scrap pieces to determine the optimal settings for achieving the desired results.

Design considerations: Rubber sheets allow for intricate designs and fine details. You can engrave text, logos, patterns, or even photographs onto the rubber surface. Keep in mind that the engraved design should be suitable for the intended application of the rubber sheet, such as stamp making, artwork, or prototyping.

Safety precautions: Laser engraving involves the use of high-powered lasers, so it is crucial to follow safety guidelines and wear appropriate protective equipment. This includes safety glasses to protect your eyes from laser radiation and proper ventilation to remove any fumes generated during the engraving process.

Post-processing: After engraving, you may need to clean the rubber sheet to remove any debris or residue. Depending on the type of rubber sheet, you might also consider applying a sealant or coating to enhance the durability and longevity of the engraved design.

Rubber sheets provide a versatile and efficient material for laser engraving applications. Whether you're creating custom stamps, artwork, or prototypes, laser engraving on rubber sheets offers precise and detailed results that can be used in various industries, including crafting, stationery, packaging, and more.

Material selection: Choose rubber sheets specifically designed for laser engraving. These sheets are typically made from laser-engravable rubber compounds that produce clean and precise engravings when exposed to a laser beam. Ensure that the rubber sheet is compatible with the type of laser engraving machine you are using.

Thickness: Rubber sheets for laser engraving come in various thicknesses. Thicker sheets are more durable and can withstand multiple engraving passes, while thinner sheets allow for finer details. Consider the depth and level of detail required for your engraving project when selecting the appropriate thickness.

Engraving settings: Adjust the laser engraving machine settings according to the specific rubber sheet being used. Parameters such as laser power, speed, and frequency may vary depending on the rubber sheet's composition and thickness. It's important to conduct some test engravings on scrap pieces to determine the optimal settings for achieving the desired results.

Design considerations: Rubber sheets allow for intricate designs and fine details. You can engrave text, logos, patterns, or even photographs onto the rubber surface. Keep in mind that the engraved design should be suitable for the intended application of the rubber sheet, such as stamp making, artwork, or prototyping.

Safety precautions: Laser engraving involves the use of high-powered lasers, so it is crucial to follow safety guidelines and wear appropriate protective equipment. This includes safety glasses to protect your eyes from laser radiation and proper ventilation to remove any fumes generated during the engraving process.

Post-processing: After engraving, you may need to clean the rubber sheet to remove any debris or residue. Depending on the type of rubber sheet, you might also consider applying a sealant or coating to enhance the durability and longevity of the engraved design.

Rubber sheets provide a versatile and efficient material for laser engraving applications. Whether you're creating custom stamps, artwork, or prototypes, laser engraving on rubber sheets offers precise and detailed results that can be used in various industries, including crafting, stationery, packaging, and more.

Return Policy

Learn more:https://acmerlaser.com/pages/refund-policy

Reviews