Written by Kevin - Published on Mar 22, 2024

What is the Difference Between Diode and CO2 Laser Engraver

Laser engraving has become an increasingly popular method for creating intricate designs on various materials such as wood, metal, and more. With advancements in technology, different types of laser engravers have emerged, each with its own set of advantages and applications. In this article, we will explore the difference between two commonly used types of laser engravers: diode laser engraver and CO2 laser engraver. We will delve into their functionalities, capabilities, and which one might be the best fit for your specific needs.

Understanding Laser Engraving Technology

Before we dive into the specifics of diode and CO2 laser engravers, let's briefly understand the technology behind laser engraving. Laser engraving involves using a high-powered laser beam to remove material from the surface of an object, resulting in a permanent etched or engraved mark. This process is highly precise and allows for intricate designs and details.

Laser engravers are widely used in industries such as manufacturing, arts and crafts, jewelry making, and more. They offer numerous advantages, including speed, accuracy, and versatility, making them a preferred choice for many professionals and enthusiasts.

Diode Laser Engraver

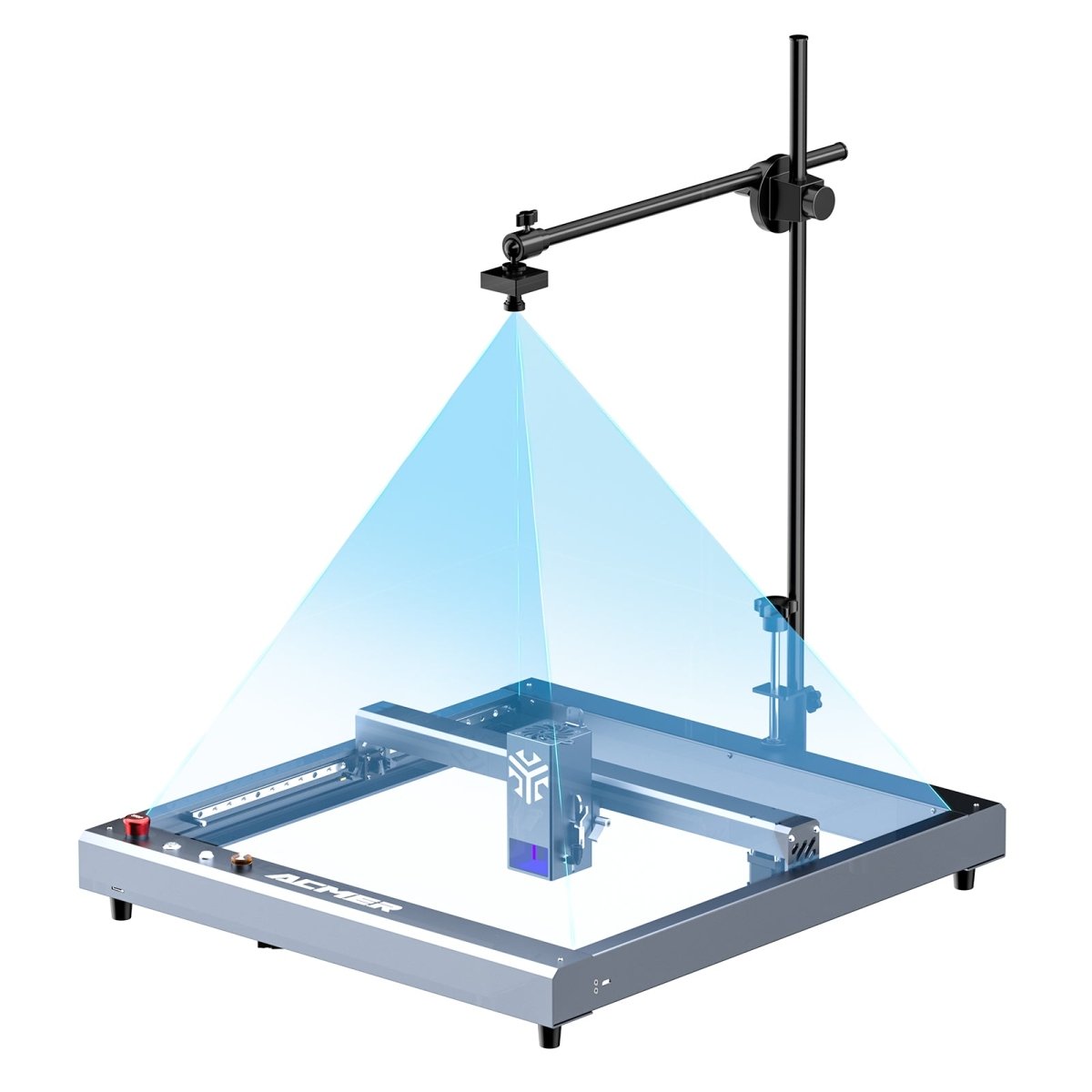

Diode laser engravers are compact and portable machines that utilize diode-pumped solid-state (DPSS) laser technology. These engravers feature a laser diode as the light source, typically a semiconductor laser. Diode laser engravers are known for their efficiency, affordability, and ease of use. They are often used for small-scale applications and are suitable for engraving on materials like wood, leather, and some plastics.

Key Features of Diode Laser Engravers

1. Power: Diode laser engravers typically have lower power outputs compared to CO2 laser engravers. They range in power from a few watts to about 20 watts, making them suitable for light-duty applications. But there are also powerful laser engraving machines, such as the ACMER P2 33w, which has a maximum power of 36 watts.

2. Size and Portability: Diode laser engravers are compact and lightweight, making them easy to transport and suitable for desktop use.

3. Maintenance: These machines require minimal maintenance due to their solid-state design and lack of gas components.

4.Cutting Capability: While diode laser engravers can cut through thin materials like paper or thin fabrics, their primary strength lies in engraving and marking.

Applications of Diode Laser Engravers

Diode laser engravers are commonly used in the following applications:

1. Personalized Gifts: They are ideal for engraving designs, text, or photographs on wooden plaques, keychains, and other small gift items.

2. Arts and Crafts: Diode laser engravers are popular among hobbyists and artists for creating intricate designs on wood, leather, and acrylic materials.

3. Prototyping: These machines are suitable for rapid prototyping and small-scale production of custom parts and components.

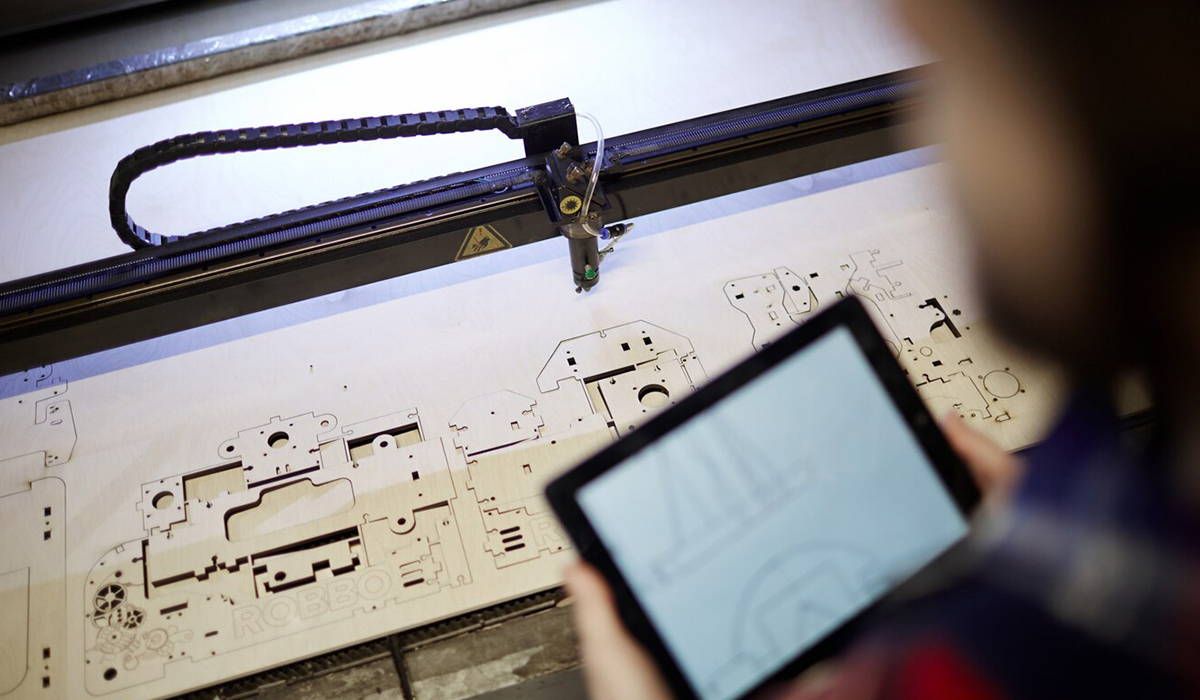

CO2 Laser Engraver

Key Features of CO2 Laser Engravers

1. Power: CO2 laser engravers have higher power output, typically ranging from 40 watts to several hundred watts, allowing for faster engraving and cutting speeds.

2. Versatility: These machines can handle a wide variety of materials and thicknesses, making them suitable for diverse applications.

3. Size and Stability: CO2 laser engravers are often larger and more stable compared to diode laser engravers, which can impact their portability and space requirements.

4. Cutting Capability: CO2 laser engravers excel in cutting various materials, including wood, acrylic, leather, and fabric.

Applications of CO2 Laser Engravers

CO2 laser engravers find applications in numerous industries and fields:

1. Signage and Advertising: They are commonly used for engraving and cutting materials used in signage, such as acrylic, wood, and foam board.

2. Woodworking: CO2 laser engravers can create intricate designs on wooden furniture, decorative items, and personalized wooden gifts.

3. Industrial Prototyping: These machines are capable of rapid prototyping and production of custom parts for various industries.

4. Textile and Fashion: CO2 laser engravers can etch intricate patterns and designs on fabrics, leather, and other textiles.

What Files Do Laser Cutters Use?

Laser cutters and engravers use specific file formats that contain the design information to be engraved or cut. The most commonly used file formats for laser cutting and engraving are:

Conclusion

In summary, both diode laser engravers and CO2 laser engravers have their own strengths and applications. Diode laser engravers are compact, affordable, and suitable for light-duty engraving on materials like wood and leather. On the other hand, CO2 laser engravers offer higher power output, versatility, and the ability to cut through a wide range of materials.

When choosing between the two, consider factors such as your specific engraving needs, the type of materials you'll be working with, and your budget. Ultimately, the right choice will depend on the level of detail, speed, and cutting capability required for your projects.

Laser engraving technology continues to advance, providing new possibilities and opportunities for creative individuals and industries. Whether you opt for a diode laser engraver or a CO2 laser engraver, these machines can elevate your craftsmanship and bring your designs to life on various materials, including wood, metal, and more.

FAQs (Frequently Asked Questions)

1. What is the main difference between a diode laser engraver and a CO2 laser engraver?

The main difference lies in the type of laser technology used. Diode laser engravers utilize a semiconductor laser diode as the light source, while CO2 laser engravers use carbon dioxide gas as the laser medium. This difference affects factors such as power output, cutting capabilities, and the range of materials that can be engraved.

2. Which materials are suitable for engraving with a diode laser engraver?

Diode laser engravers are well-suited for engraving on materials such as wood, leather, and some plastics. Their lower power output makes them ideal for light-duty applications and smaller-scale projects.

3. What are the advantages of using a CO2 laser engraver?

CO2 laser engravers offer higher power output, allowing for faster engraving and cutting speeds. They are also more versatile, capable of engraving and cutting a wide range of materials, including wood, acrylic, glass, and fabric. Additionally, CO2 laser engravers are often used in industries that require larger-scale production and the ability to work with thicker materials.

4. Can laser engravers cut through metal?

While diode laser engravers are generally not powerful enough to cut through metal, CO2 laser engravers can effectively cut thin sheets of metal. However, it's important to note that the thickness and type of metal will impact the cutting capabilities, and specialized laser systems may be required for industrial metal cutting applications.

4. What file formats should I use for laser engraving?

Laser engravers primarily work with vector file formats, such as SVG, AI, PDF, and DXF. These formats define shapes and lines using mathematical formulas, allowing for precise and scalable designs. Raster formats like JPG, PNG, and BMP can also be used for engraving, but they are better suited for images rather than intricate designs or cutting.

Related blogs