Written by Kevin - Published on Mar 15, 2024

How to Use ACMER Laser Cutter to Cut Acrylic Sheets

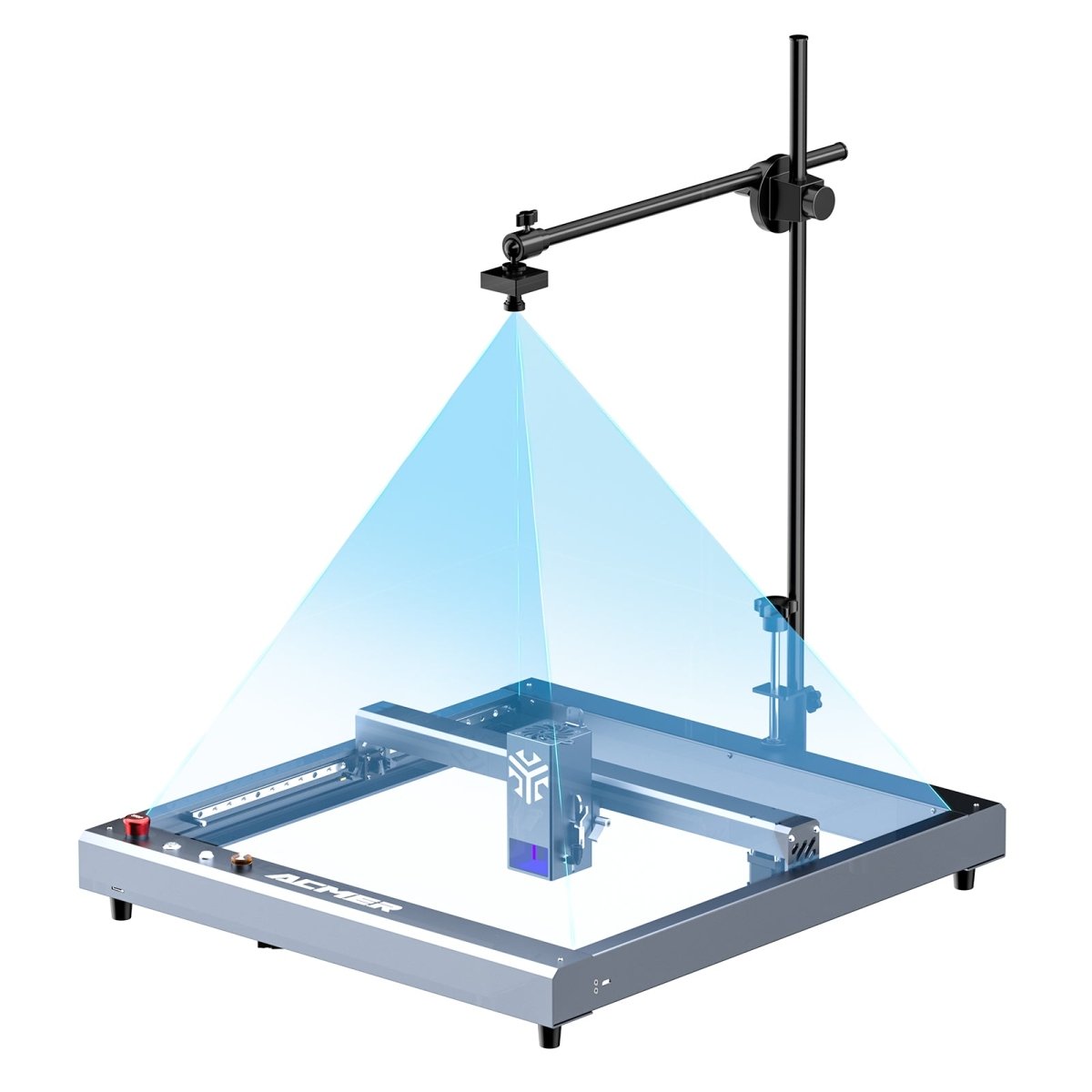

Acrylic sheets are versatile materials widely used in various industries, from signage to fabrication. Precision cutting of acrylic sheets is crucial for achieving desired shapes and designs. ACMER Laser Cutter provides a reliable solution for cutting acrylic sheets with precision and efficiency. We'll explore the step-by-step process and considerations for effectively cutting acrylic sheets with an ACMER laser cutter.

Understanding Acrylic Sheets

Before diving into the cutting process, it's essential to understand the properties of acrylic sheets. Acrylic, also known as Plexiglas or Perspex, is a transparent thermoplastic known for its durability and clarity. It comes in different thicknesses and colors, offering flexibility in design and application.

Understand the Features and Preparations of ACMER Laser Cutting Machine Features

1. 33-36w High-powered laser beam for swift and precise cutting.

2. Industrial-grade guide rails ensure movement accuracy.

3. The highest speed is 30000mm/min to adapt to different acrylic sheet thicknesses.

4. The 420*400 engraving area meets most engraving scenarios and uses.

Necessary Equipment

Before operating the ACMER P2 33w Laser Cutter, ensure you have the necessary equipment at hand:

1. Safety goggles to protect your eyes from laser radiation.

2. Heat-resistant gloves for handling hot materials.

3. Fire extinguisher for emergencies.

Safety Gear

Always wear appropriate safety gear, including:

1. Closed-toe shoes to protect your feet.

2. Long-sleeved clothing to minimize skin exposure.

3. Ear protection to reduce noise levels.

Checking the ACMER Laser Cutter Settings

Adjusting Laser Settings

Determining Power and Speed Settings

Depending on the thickness and type of acrylic sheet being used, adjust the laser power and speed settings accordingly. Please refer to ACMER's parameter settings for detailed recommended settings.Because there may be a small error in the parameter settings, in order to achieve perfection in your work, before cutting the actual acrylic sheet, please make a test cut on the scrap to ensure that the settings are correct. Adjust as necessary until desired cut quality is achieved.

Cutting for Use with C4 Air Assist Pump

If you want your work to be even more perfect, be sure to turn on the air-assist pump option while cutting. With the help of an air pump, the exhaust gases produced by cutting will greatly reduce the impact on your work.

Cutting for Use with R10 Enclosure Box

Cutting will produce a lot of smoke and toxic gases. If you don’t want to affect your or other people’s health, you can use it with the R10 Enclosure Box.

Use Genuine Lightburn Software

If you want to buy a permanent genuine lightburn software gcode, then you can buy it at ACMER, and you can get a 5% off coupon. Discount code: PM29BAJ47V7N.

Monitoring the Laser Cutter

Throughout the cutting process, keep an eye on the laser cutter to ensure that everything is running smoothly. Make adjustments as needed to maintain optimal cutting performance.

Post-Cutting Procedures

Tips for Optimal Results

1. Always use high-quality acrylic sheets for best results.

2. Keep the cutting area well-ventilated to prevent the accumulation of fumes.

3. Regularly clean and maintain the ACMER Laser Cutter for optimal performance.

Troubleshooting Common Issues

1. If the cut edges are rough or uneven, adjust the laser power and speed settings.

2. If the acrylic sheet melts or warps during cutting, reduce the power or increase the speed of the laser.

Maintenance of ACMER Laser Cutter

Creative Applications of Laser-Cut Acrylic

Comparison with Other Cutting Methods

Conclusion

Cutting acrylic sheets with an ACMER laser cutter can make cutting your pieces easier, but it requires careful preparation and attention to detail. By following the steps outlined in this guide, you can achieve more precise, clean cuts for your pieces, resulting in a more finished piece.

FAQs (Frequently Asked Questions)

1. Can ACMER Laser Cutter cut other materials besides acrylic?

Yes, ACMER Laser Cutter is capable of cutting various materials, including wood, plastic, and leather.

2. What safety precautions should I take when using the ACMER Laser Cutter?

Always wear protective gear, ensure proper ventilation, and follow all safety guidelines provided by the manufacturer.

3. Can I use ACMER Laser Cutter for engraving acrylic sheets as well?

Yes, ACMER Laser Cutter can be used for both cutting and engraving acrylic sheets.

4. How thick of an acrylic sheet can ACMER Laser Cutter cut?

Cut thickness may vary depending on the specific model of ACMER laser cutting machine. See ACMER's specifications for details, for example the ACMER P2 33w can cut acrylic up to 30mm thick.

Related blogs